An Introduction to Producer Responsibility

Producer Responsibility is a policy concept that aims to reduce waste disposal costs for local governments, increase the convenience and accessibility of recycling programs, and create incentives for manufacturers to design sustainable, less toxic, and more easily recyclable or reusable products and packaging.

Under our current waste and recycling system in the US, the costs to manage waste and recycling programs fall upon local governments, residents, and businesses. Yet these communities have no control over the design of products and packaging, how well they can be recycled, and at what costs.

A Producer Responsibility—or Extended Producer Responsibility (EPR)—system shifts the financial burden to product manufacturers who become responsible for designing, financing, and managing recycling programs for their products. Because producers now have a financial stake in the success of local recycling programs, they are incentivized to design products to be more recyclable. While the producers have full responsibility for creating, funding, and maintaining recycling programs, EPR programs are commonly overseen by national or state governments that set performance goals to ensure accountability and transparency.

Check out the Product Stewardship Institute to read more about the principles of Producer Responsibility and the roles of producers, governments, retailers, and consumers under EPR systems.

How Producer Responsibility Fits into a Zero Waste System

EPR is a key element of a Zero Waste system because it works to reduce waste at both the downstream and upstream points of impact. On the downstream side, EPR policies increase the convenience and accessibility of recycling, which reduces waste disposal. This is where local governments and consumers most commonly interact with and see the benefits of an EPR system. But the majority of our waste is actually produced in the design and manufacturing process, what we call the upstream impacts. Here, EPR policies encourage more efficient resource use and sustainable manufacturing processes, which can greatly reduce the vast amounts of waste generated from mining, drilling, or harvesting virgin resources to make new products.

How a Producer Responsibility System Works

For many hazardous and hard-to-recycle materials such as electronics or paint, residents have to pay a fee to recycle or dispose of these materials when they are no longer in use. This discourages participation and creates frustration for residents. Instead, under many Producer Responsibility systems for hard to recycle items, producers charge a small fee to consumers upon purchase of a product, and then use the fee to develop or expand recycling programs. Under some Producer Responsibility systems, like those for packaging and paper recycling, the cost of the program is rolled into the cost of doing business and customers don’t ever see an increase in price or a fee. Now residents can recycle their product at no charge at its end of life, which increases recycling participation, reduces waste, and ensures materials are responsibly recycled or disposed of.

Local Governments Save Money, Increase Recycling with Producer Responsibility Systems

Local communities benefit from Producer Responsibility programs in two primary ways—cost savings and more convenient recycling. Under an EPR system, producers are in charge of paying for the costs to collect and recycle their materials, either by running the collection system themselves or by paying the municipality or another party to collect, transport, and recycle materials. This can significantly reduce costs to cities as well as the burden on taxpayers. For example, many EPR programs have been designed around paint, batteries, mercury-containing products like light bulbs, and other products typically collected through household hazardous waste (HHW) programs. HHW programs are traditionally very expensive for local governments to operate because the materials collected are toxic and require special disposal or recycling processes. Cities save substantially on disposal costs and avoided collection costs for HHW materials under an EPR program—the Product Stewardship Institute estimates that local governments save nearly $2 per person under EPR programs for paint, for example.

Second, EPR programs benefit communities by providing new, more convenient recycling services. With a dedicated funding source to manage the recycling of their products, manufacturers are able to provide recycling programs at more locations that make it convenient and accessible for residents, particularly in rural areas.

One notable illustration of these benefits is attributable to the state of Connecticut. The Product Stewardship Institute’s 2017 study on four EPR programs in Connecticut found that the programs yielded a cumulative cost savings of more than $2.6 million per year for Connecticut municipalities. Additionally, nearly all Connecticut residents now have convenient access to collection sites for the targeted products.

History of Producer Responsibility Programs

EPR programs began in Europe more than 20 years ago and have now spread to every continent. EPR policies in the EU have been highly successful at increasing the recycling of packaging—by 2010, the EU was recycling over 60% of packaging in countries with EPR systems.

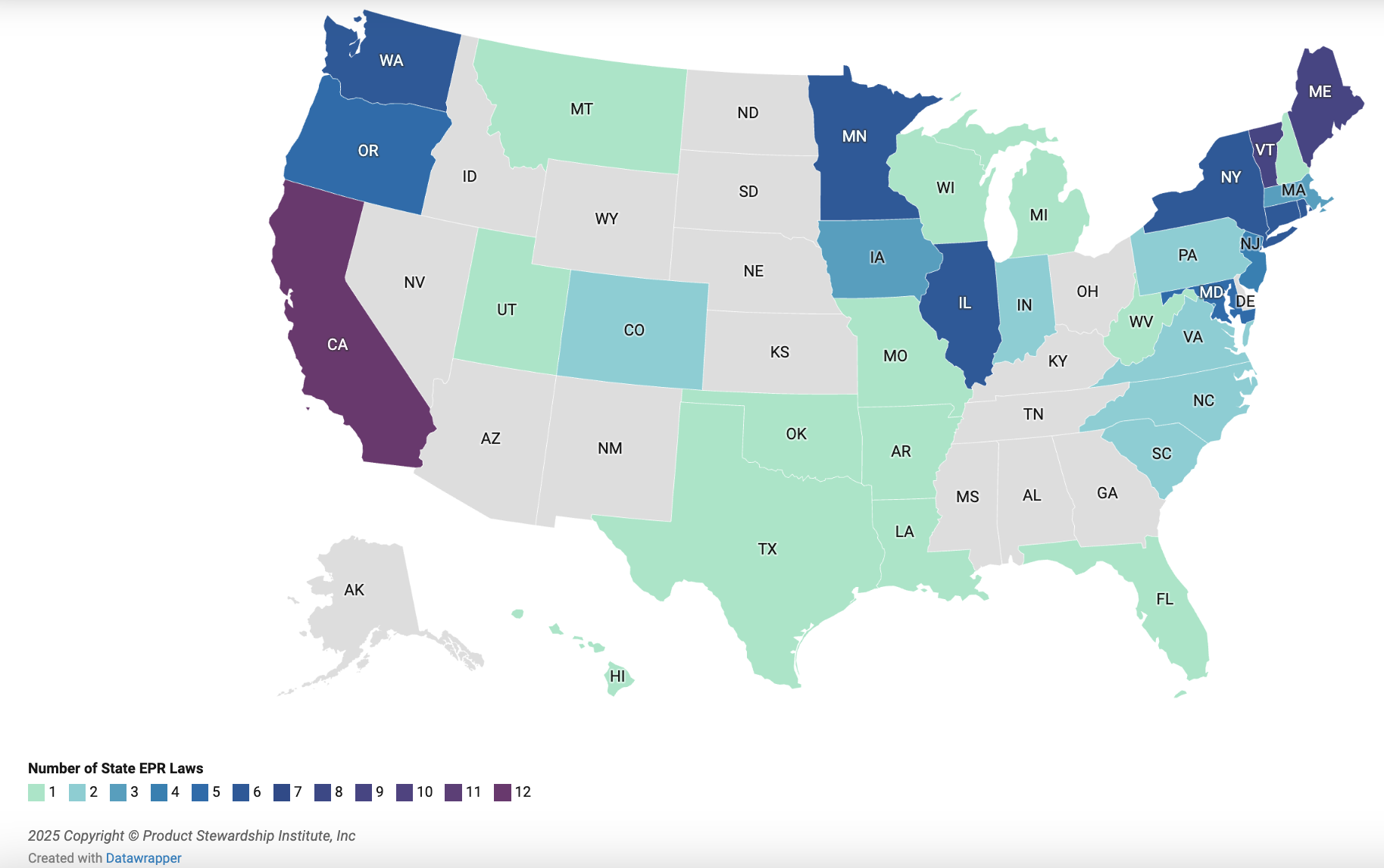

In 2019, there were over 115 EPR policies across 33 states in the US, a tremendous increase from only 7 policies in 2001. These policies target 15 different types of products, including bulky or hard-to-recycle materials such as electronics, paint, mattresses, carpet, fluorescent lighting, and pharmaceuticals. EPR policies have been endorsed by the Environmental Council of the States (ECOS), the National Association of Counties (NAC), the National League of Cities (NLC), and the US Council of Mayors (USCM).

For information on more states and product categories, check out the Product Stewardship Institute’s EPR Laws Map.

Examples of Producer Responsibility in Action in the US

- Electronics: EPR policies are in place in 24 states. Electronic waste contains toxic substances such as lead, mercury, and brominated flame retardants, which threaten public health and the environment if not properly managed when no longer in use. These policies save local governments millions of dollars, create jobs in recycling, and protect our environment.

- Mattresses: EPR policies are in place in three states. In the US, more than 50,000 mattresses are thrown away each day, less than 5% of which are recycled. These policies are targeted to help develop the necessary infrastructure and markets to manage these bulky items and reduce illegal dumping.

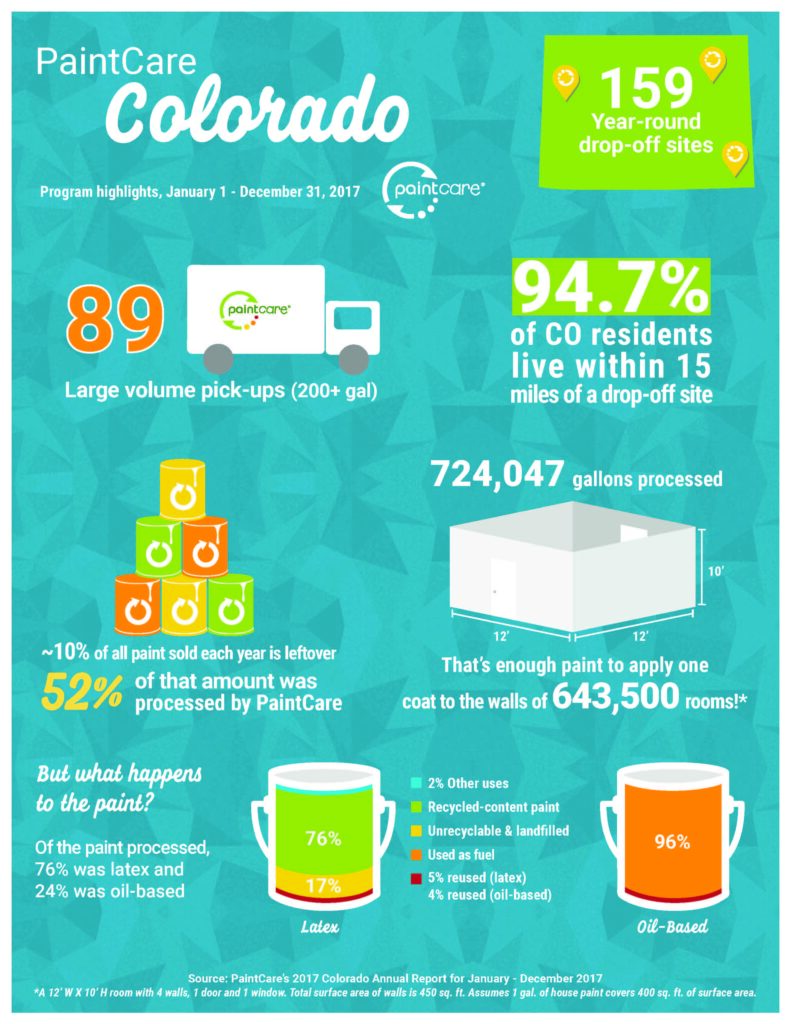

- Paint: EPR policies are in place in 10 states. In Colorado, manufacturers charge a small fee of 75 cents per gallon of paint to fund collection infrastructure. Now nearly 95% of the state has access to paint recycling within 15 miles.

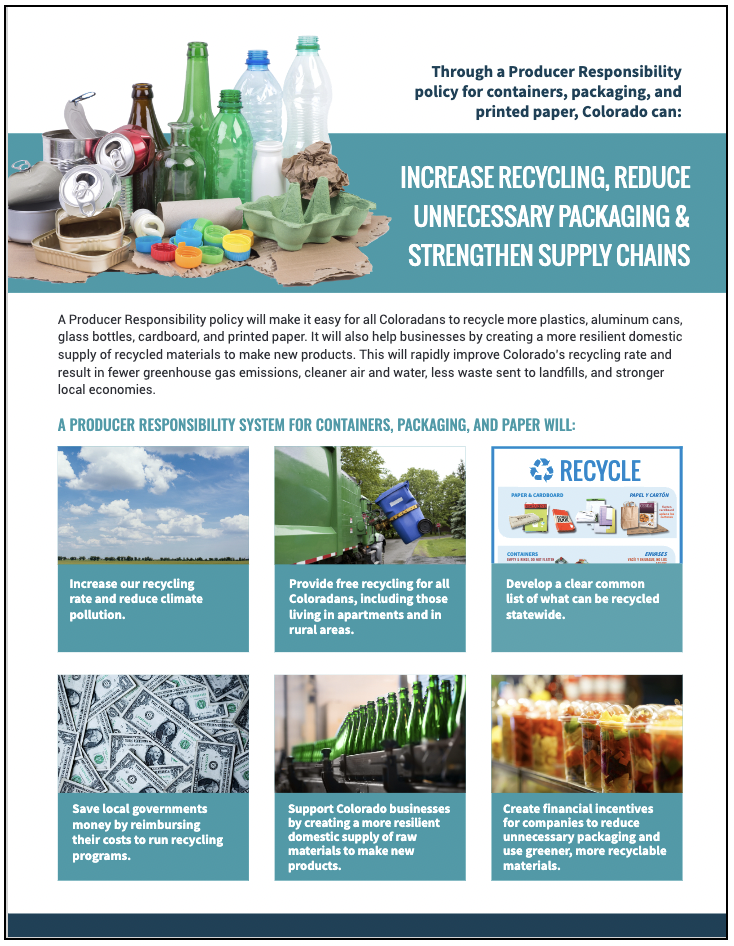

- Packaging and Paper: Packaging and paper: Colorado became the third US state to adopt a policy for packaging (cans, bottles, boxes, etc.) and printed paper (junk mail, magazines, etc.) in 2022. The policy, HB22-1355, will provide free recycling access to all Coloradans starting in 2026. Municipalities, state government, environmental groups, waste industry experts and producers of packaging and paper worked together to draft the legislation and are working to implement the program now. Learn more about this coalition effort at RecyclingForAllColoradans.org.

In Colorado, EPR for paint has increased access and collection rates. Source: PaintCare